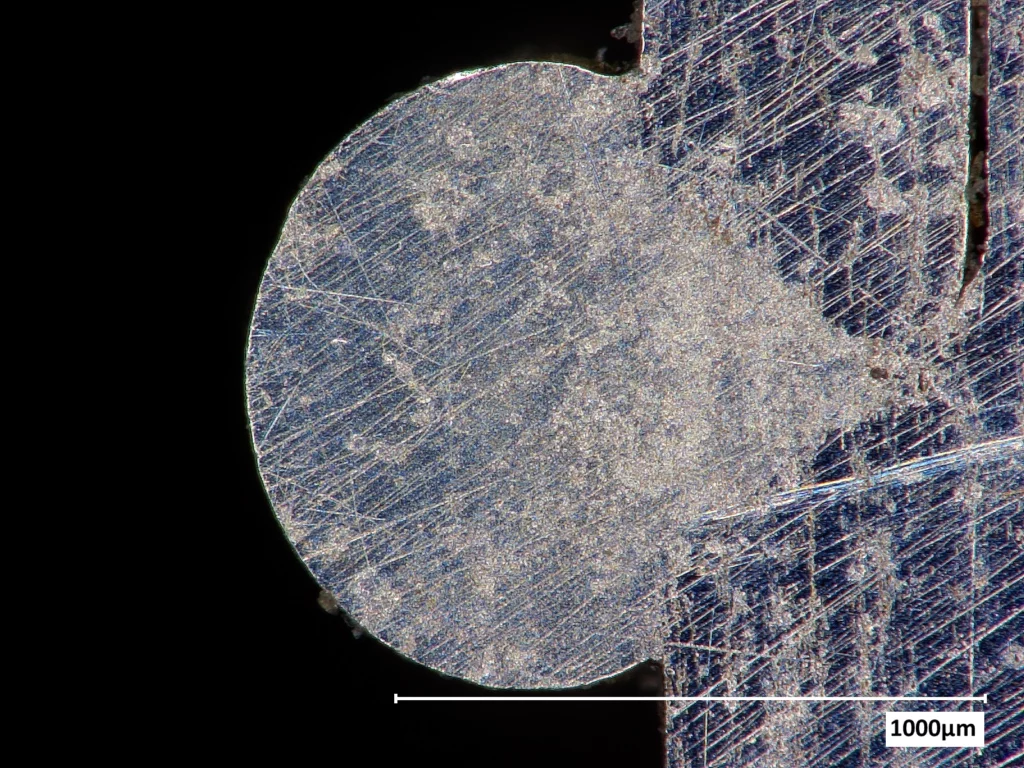

Aluminum housing

AlSiMg

Along with the more expensive titanium, aluminum is a key material for the aerospace industry and instrumentation applications. Electron beam welding is the ideal method for joining AlSiMg parts in a vacuum-tight manner. The high-strength and lightweight AlSiMg alloy is widely used in thin-walled and complex structures in aerospace and automotive components. Electron beam welding machines from FOCUS enable precise connections of even the most complex geometries and are therefore indispensable for high-precision requirements.

The electron beam welding process takes place in a vacuum, which avoids environmental influences on the seam. This ensures defect-free and strong connections, which is particularly important for the most demanding applications. The precise heat supply and dosage ensures that electronics and contacts neither overheat nor become distorted.

In addition to turnkey welding systems, FOCUS also offers contract welding.