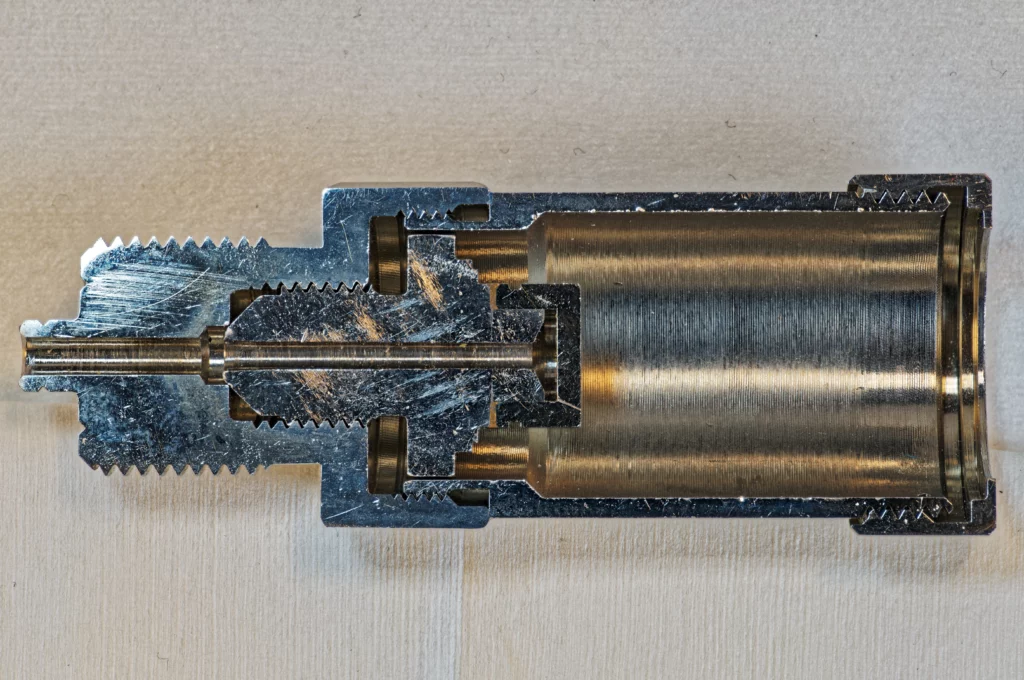

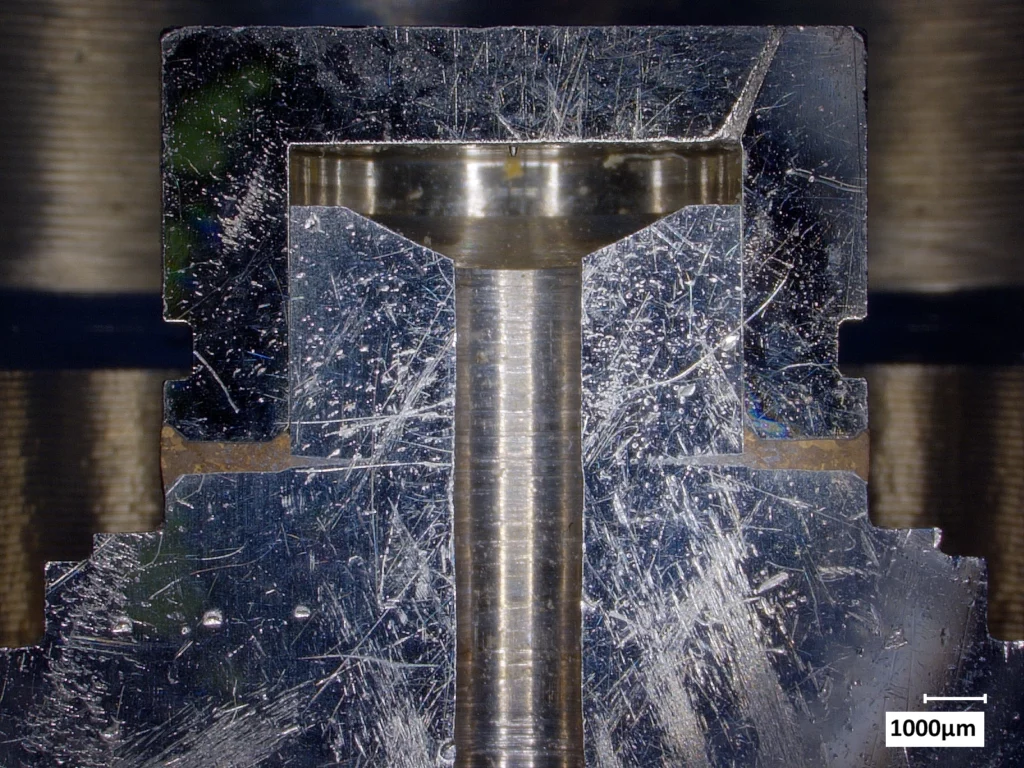

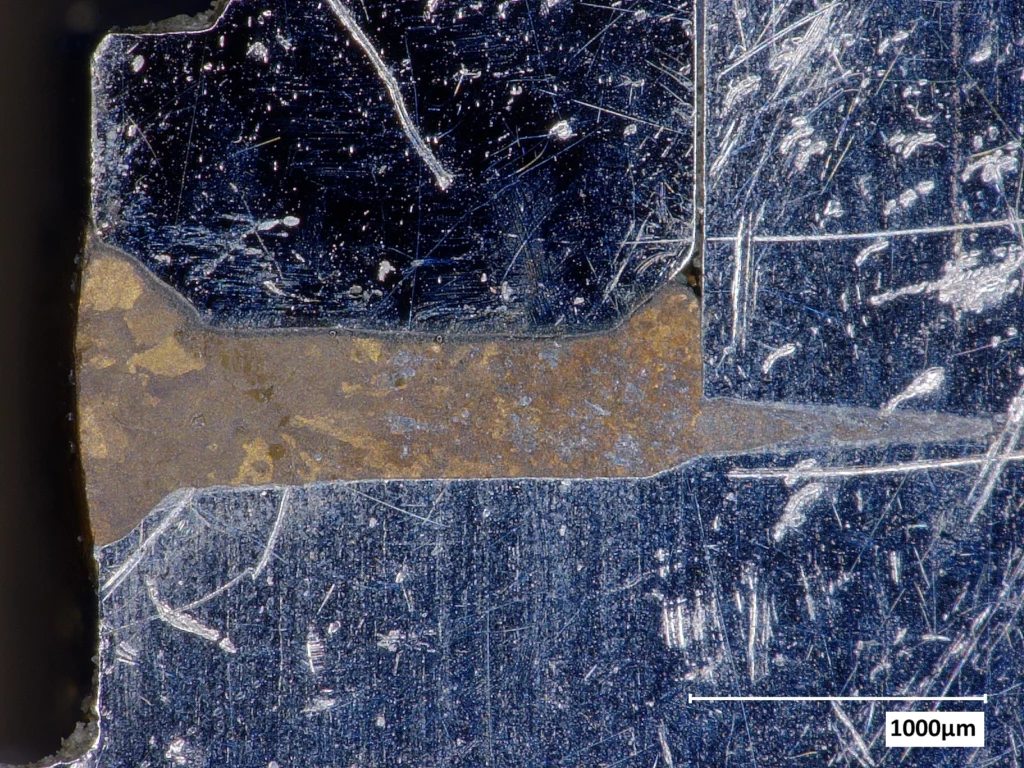

What is one of the most important points when welding and assembling sensors for most demanding industrial applications? It is the quality of the connection as well as its high reliability and repeatability of the welding process. Various materials are used during sensor assembly used; They all have one thing in common – they need excellence quality of electron beam welding. Whether stainless steel (stainless steel) with copper, steel with Stainless steel, axial/radial welds or complex welds – the high precision Electron beam welding machines from FOCUS allow you to adjust the beam size and to control the beam power as precisely as possible for the perfect results.

With the unique 2 kW power supply, an infinitely adjustable beam voltage from 5 to 60 kV (and minimum step size of 20 V) and a beam current of 15 µA to 33 mA (and minimum step size of 10 µA), the FOCUS electron beam generator is the heart of our systems and is a precision welding device for the most demanding applications. With the FOCUS electron beam generator you get a beam diameter down to 25 µm – and it is ensured that at every single point on the welding path perfect blasting conditions can be achieved.

FOCUS is the world’s leading manufacturer of precision -Electron beam welding equipment and has extensive experience in welding a variety of Sensors. We are happy to carry out test welds on your products so that you You can be sure that FOCUS electron beam welding technology meets your requirements.