Deep Welding

Stainless Steel

What is deep welding?

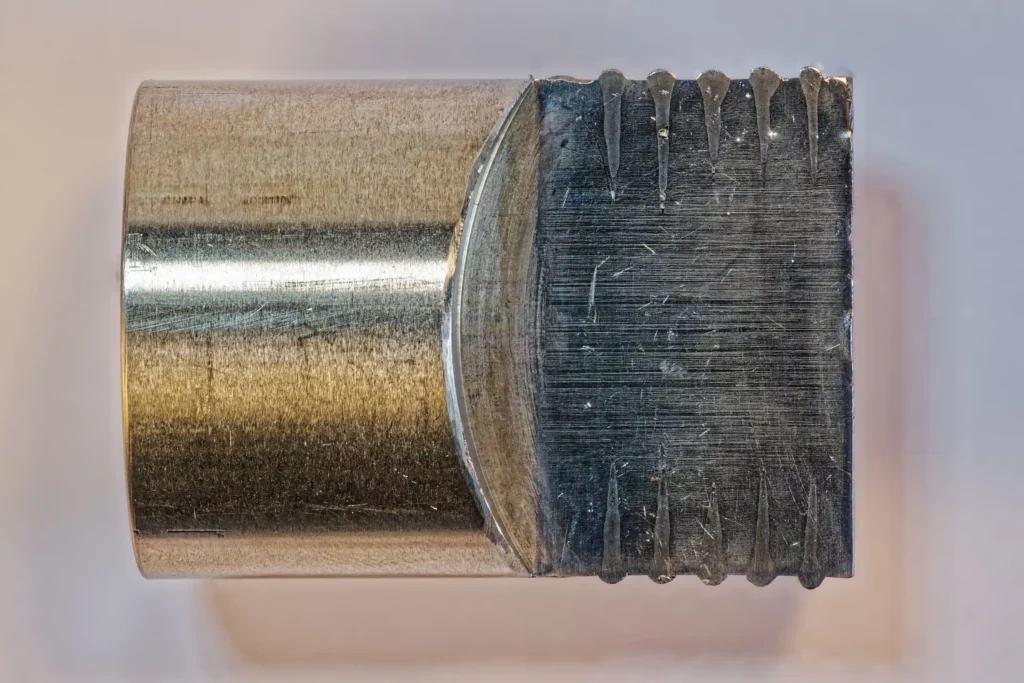

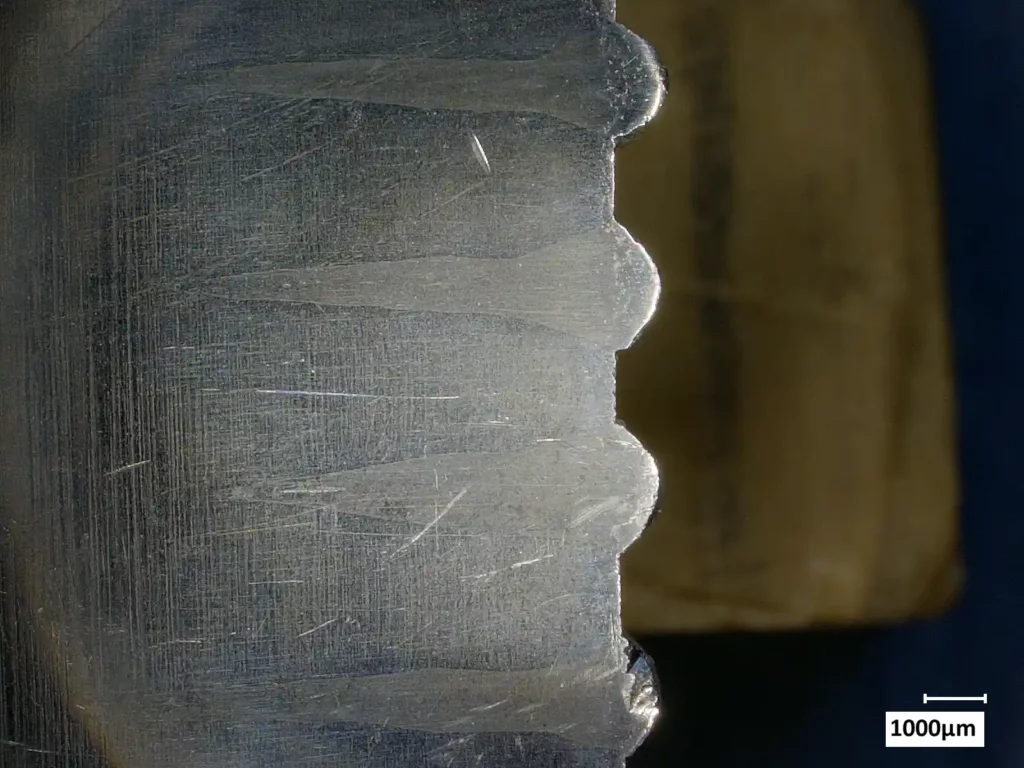

Electron beam welding is called deep welding due to the nature of the process and the results achieved. One of the key characteristics of electron beam welding is the ability to achieve very deep welds with relatively small heat affected zone widths. Typical penetration depth to width ratios can be up to 10:1 or even higher depending on welding parameters and material properties.

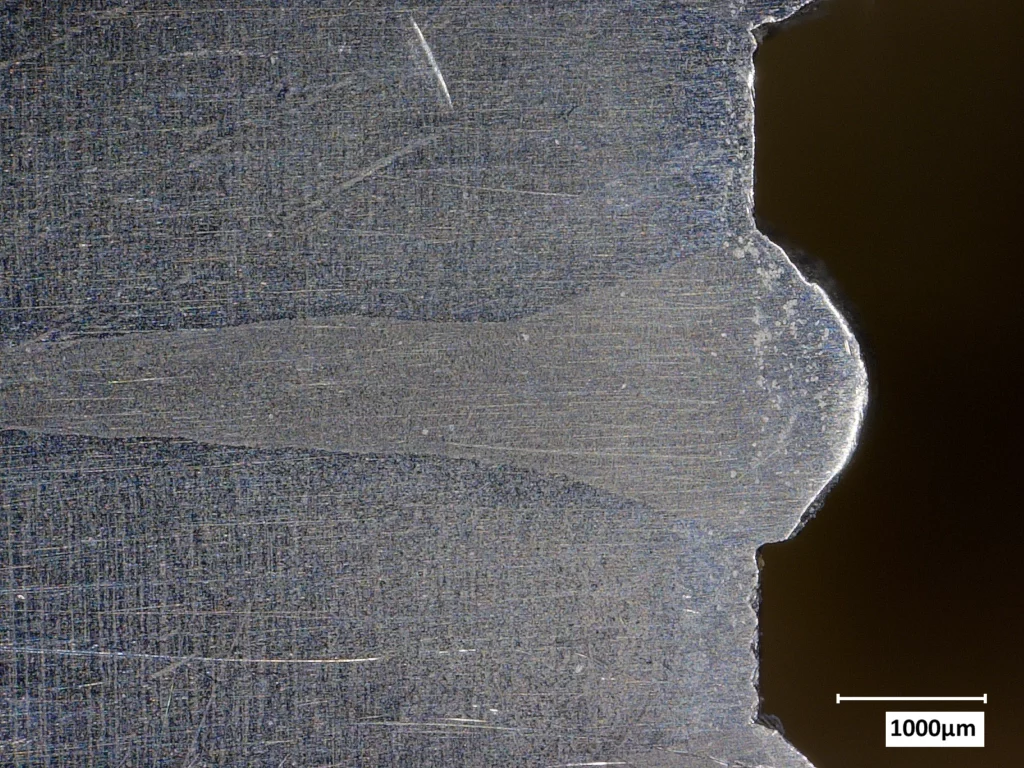

The electron beam has a high energy density that effectively melts and vaporizes the material with minimal impact on the surrounding material. Using a vacuum environment lowers the metal’s boiling point and vapor pressure during welding. This allows a narrow and deep weld to be created.

At FOCUS, we are experts in precise electron beam welding – a type of connection in which the entire heat-affected zone does not exceed a few hundred micrometers and the weld spot size ideally does not exceed 50 µm.

Because electron beam welding directs the energy precisely into the welding zone, the overall heat effect on the material is minimized. This leads to a narrow heat-affected zone and thus reduced thermal deformations and stresses in the connection. The task of heat dissipation when deep welding thin parts is a special challenge that we at FOCUS have successfully solved.