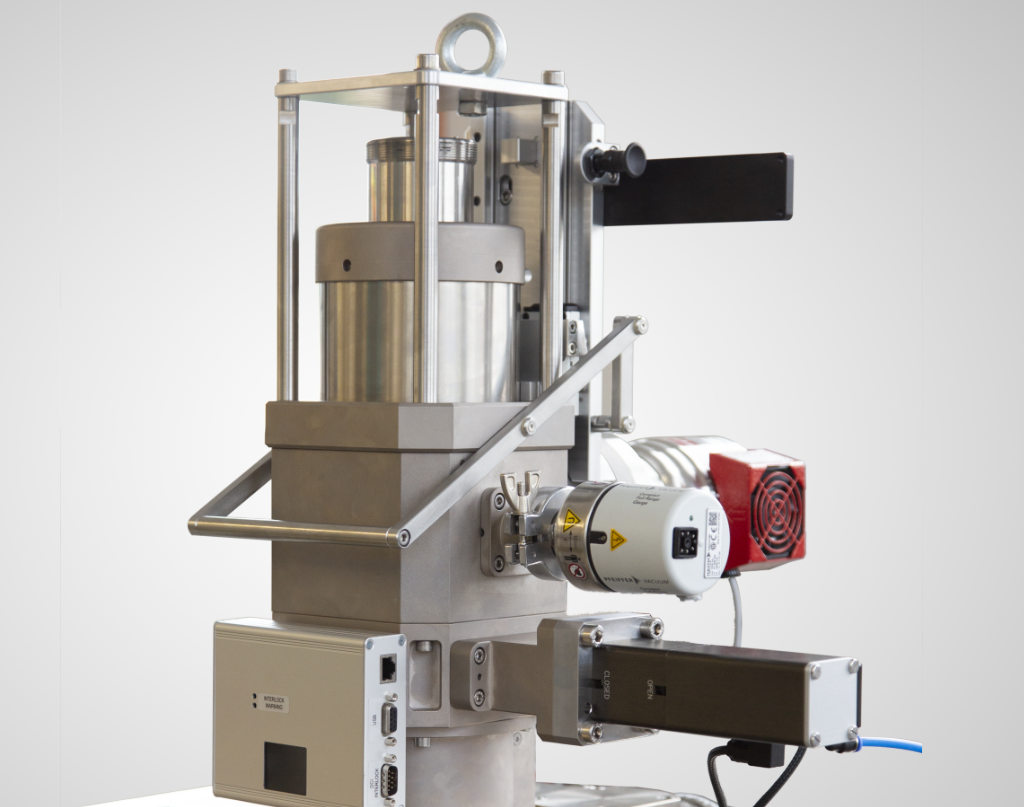

We produce a unique electron beam generator with precise beam control.

- Easily exchangeable cathode.

- Easy and fast procedure for replacing the cathode.

- Precision device for mounting the cathode (cathode mounting tool).

It consists of 2 main parts:

1) Electron gun for particularly precise beam control. Equipped with triode with a direct heated tungsten hair pin, ribbon-type or LaB6 cathode to form an axisymmetric electron beam with a small crossover, providing a circular focal spot shape during welding.

2) High voltage power supply delivers the continuously adjustable beam voltage from 5 to 60 kV (Minimum step size is 20 V). Due to the pulse mode, MICROBEAM is able to perform precise energy and heat transferring

| Spot size @ 1 mA | < 50µm |

| Min spot size | Down to 25 µm (SEM-mode) |

| Beam energy | max. 60 keV |

| Beam wattage | max. 2 kW |

| Beam current | max. 33 mA / 40mA |

| Deflection range | ± 8 to ± 15° (depending on configuration) |

| Cathode | directly heated tungsten filament (0.15 mm), directly heated ribbon filament (0.4 mm), optional LaB6 emitter |

| Flange diameter | 105 mm |

| Mains supply | Power and wattage depending on pumping |

| Conformity | CE |

| Acceleration voltage | 5 to 60 kV |

| Min. voltage step size | 20 V |

| Pulsing mode | Beam pulsing down to 10μsec pulse width; up to 5kHz pulse frequency |

| Beam current | 0.050 to 33 mA (limited by max. wattage) |

| Min. current step size | 1μA |

| Wattage | max. 2 kW |

| Wehnelt voltage | up to -1250 V |

| Filament current | max. 5 A |

| Filament voltage | max. 5 V |

| Filament wattage | max. 25 W |

For further information please contact us.