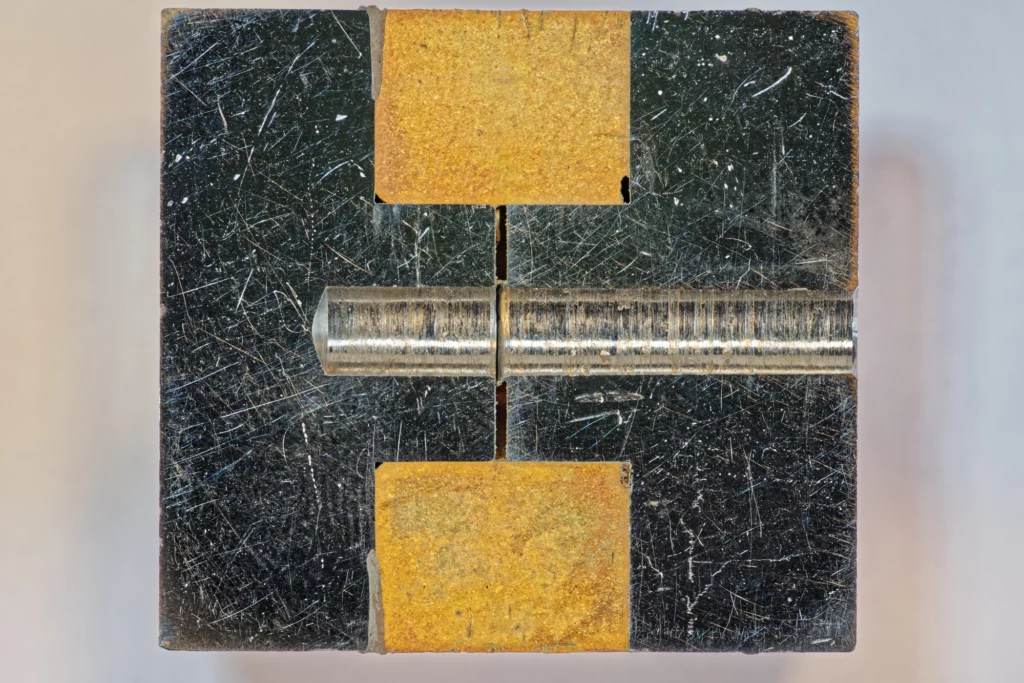

Copper to Titanium

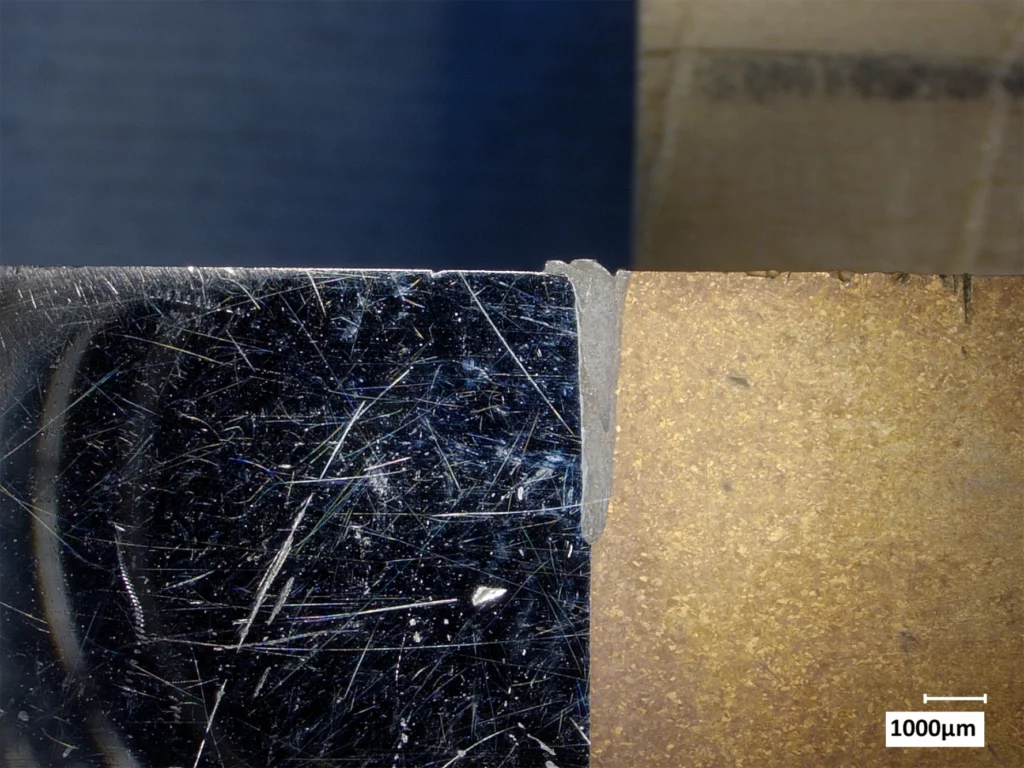

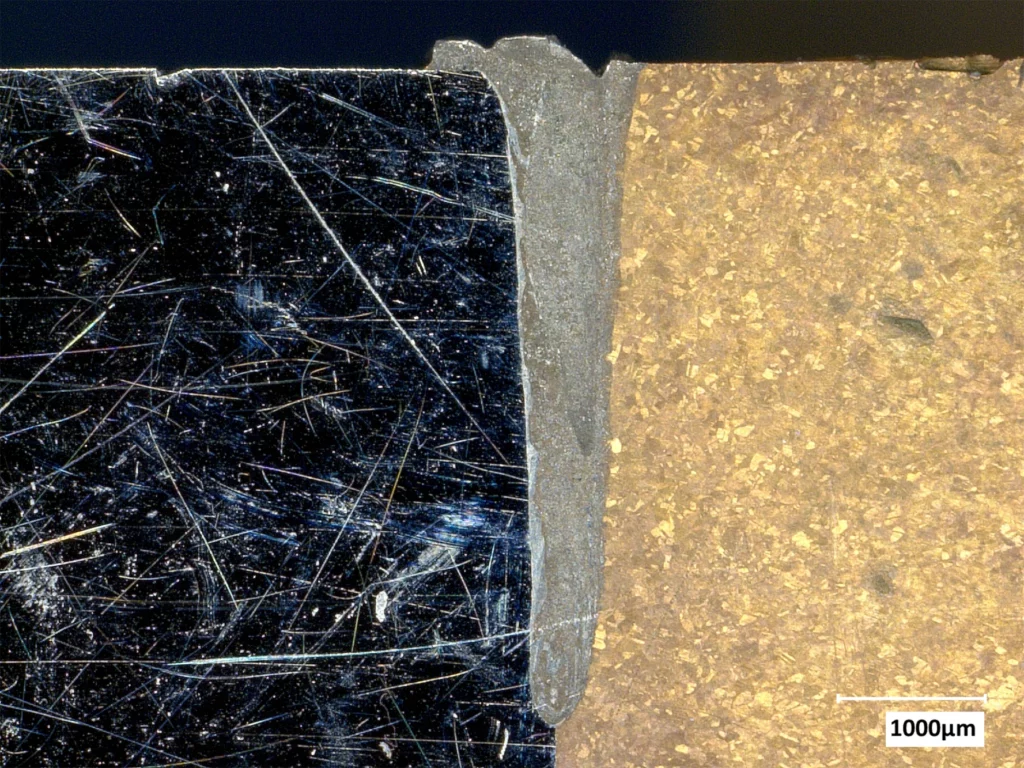

Welding different metals can be very demanding, e.g. B. welding copper and titanium. Copper has a much lower melting point than titanium (1084°C vs. 1668°C) and a much higher thermal conductivity. This leads to uneven heat distribution, which can lead to deformation and defects in the weld.

In addition, titanium, like any reactive metal, actively reacts with oxygen, which leads to the formation of oxides and can affect the quality of the weld.

Due to the vacuum environment and the possibility of rapid temperature cycling, electron beam welding helps minimize the formation of fragile intermetallic bonds.

Precise electron beam welding machines from FOCUS enable excellent control of the welding process. While they deliver exactly the right amount of heat to the right point at any time, they enable precise control of welding parameters, such as penetration depth and weld width. This is especially important when working with materials with different melting points and thermal conductivities.