From the very early days back in 1990, FOCUS has always intended to be at the forefront of technological developments. Therefore, in 2007, when FOCUS decided to expand its portfolio and become a manufacturer of electron beam welding machines, we immediately focused on the development of high-end technologies for industry and research. With a passion for innovation and an unwavering drive for quality, FOCUS quickly established itself in the market and took its place in the niche of one of the most precise and accurate electron beam welding machines with Powerbeam technology.

Our main goal has always been the ultimate control of the heat input into the welding zone.

Users can precisely dose the power (< 1 Watt) and the point of delivery of this power with a unique 2 kW (0.15…33 mA, 60 kV) … electron beam generator and a system to get the beam focused into a spot with a diameter of down to 25 µm. Precision, accuracy and repeatability are the advantages of Powerbeam electron beam welding technology, which we at FOCUS, have taken to a new level.

The company’s innovative approach continued with the launch of the LaVa (Laser in Vacuum) technology, which combines the advantages of laser welding with the stability of a vacuum environment. This welding process allows welding with deep penetration and minimal spatter, improving weld quality and making it suitable for a variety of materials, including aluminium, copper and titanium. Users of LaVa technology are often laser welding system users who have overcome the physical limitations of atmospheric or inert gas laser welding technology and are expanding their laser applications with vacuum atmosphere, achieving weld quality comparable to electron beam welding. And for some materials, such as those with magnetic properties, LaVa technology is the most pure and deep welding technology.

Often new users ask us, “What technology do you recommend to use for our task? Electron beam or laser in vacuum?”. Each technology has its own advantages and features, and we at FOCUS can offer the best – a direct comparison of electron beam welding and laser in vacuum technology. In our laboratory in Hünstetten (near Frankfurt am Main, Germany) both technologies are represented! And it’s not just the Powerbeam and LaVa welding machines, we are also ready to demonstrate the unique ELWIS [Electron & Laser Beam Welding Integrated System] research system – a machine with an extremely easily exchangeable heat source. One can use an electron beam or a laser – it takes no more than an hour to change the power source at the vacuum chamber!

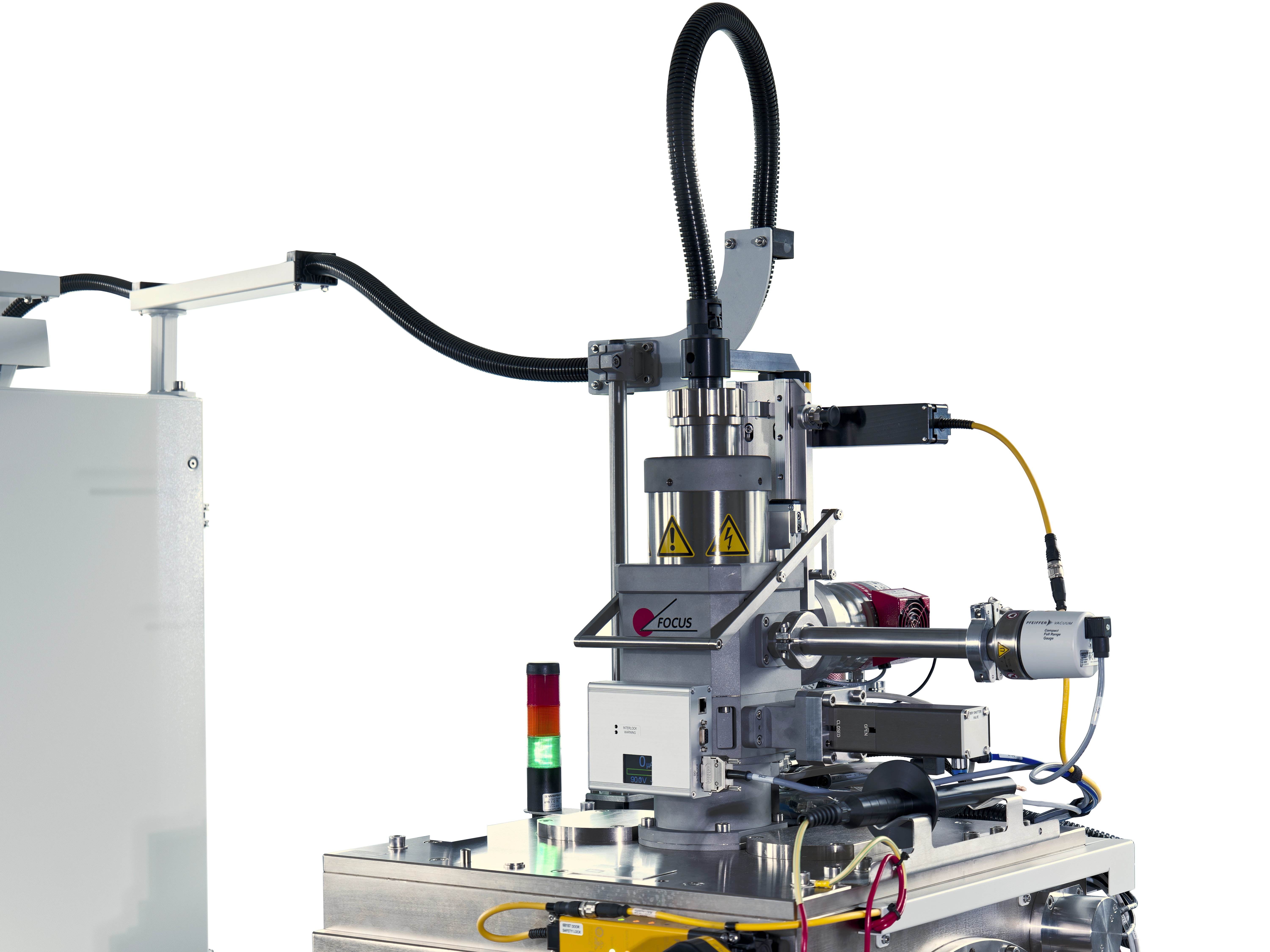

ELWIS Electron Beam Configuration

ELWIS Laser in Vacuum Configuration

ELWIS is a compact system with a footprint of only three square meters, based on an L135 working chamber with a volume of 135 liters (500 x 500 x 540 mm³), the ELWIS machine can be equipped with a large number of different CNC-controlled manipulators. These can be:

- movable X-shift heat source (both electron beam generator and laser)

- 2-axis table with X- and Y-axis movement of ±75 mm

- 4-axis table with XYZR (xy: ±60 mm, z: 0..75 mm, r: n*360°) movement and water cooling

- 1-position linear (0..200 mm) and rotary (n*360°) manipulator for axial and radial seams

- multi-position axial manipulators (6-, 10-, 12-) also for axial and radial seams

- compact rotary (n*360°) manipulator with 0…90° tilt option for axial and radial seams

- and of course, manipulators for individual tasks. For example, with integrated thermocouples, water cooling, various multi-position cells, with preloading just to mention a few

Also, the design of the chamber can be customized – we can produce a larger chamber or add modular extensions.

The flexibility of the ELWIS combined electron beam and laser in vacuum welding machine is increased by equipping the laser system with optical beam control systems such as Wobble Optics or Laser Scanner, while the electron beam generator has the ability to deflect the beam from the vertical axis by ±15° (±8° with X-shift).

The software is installed on only one control computer, which includes three main modules:

- CNC control of the motion axes using the Mach4 software package

- DacPath electron beam control program

- laser control program from laser manufacturers

When changing the configuration from electron beam to laser in vacuum welding and back again, it is only necessary to mechanically switch the two sources and then select the set configuration in the control system.

Do you have questions and want to see ELWIS live? Please contact us, we will explain more about the functions, features, possibilities and offer an online demonstration or welcome to our laboratory to see ELWIS live.

Would you like to compare two vacuum welding technologies – electron beam or laser in vacuum? Also please contact us directly and our experts will answer all your questions and offer solutions for your applications.