Joining, structuring, engraving and polishing: reliable perfection for medical!

Reliable and Clean Joining

The high requirements in the medical sector for cleanliness, reliability and high precision are addressed with the MEBW-60. Due to the contactless processing under high vacuum, contamination can be avoided or reduced to a minimum.

The technologies unique ability is shown perfectly when it comes to joining materials like stainless steel, titanium, gold and the complex task of welding shape memory alloys (Nitinol) . The microscopic quality of joints can be observed at any time with the scanning electron microscope mode (SEM) available on the micro electron beam welding machine MEBW-60 with a resolution up to about 25 µm.

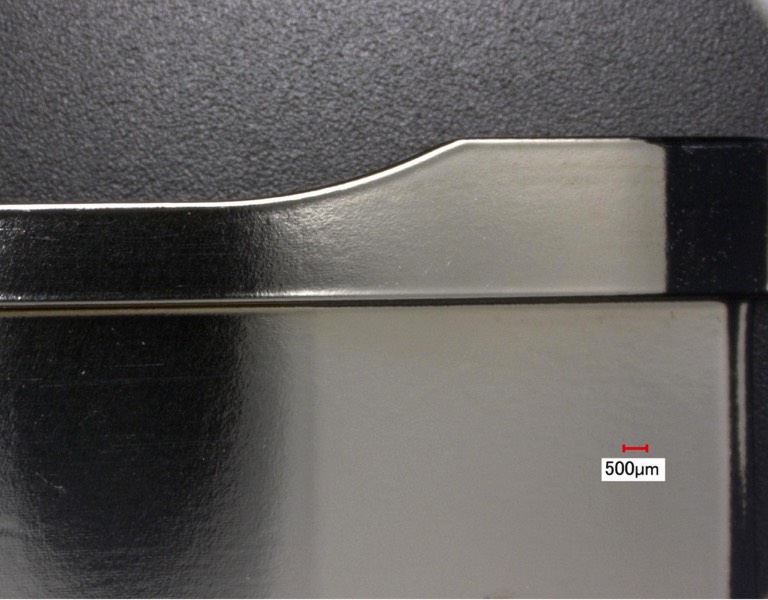

The very fine beam with as less as 30 microns allows for delicate welds as shown in the example below.

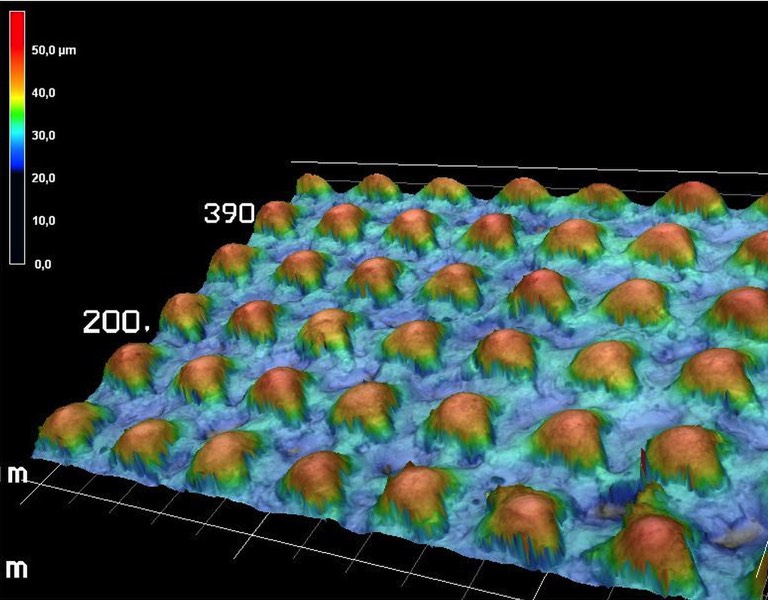

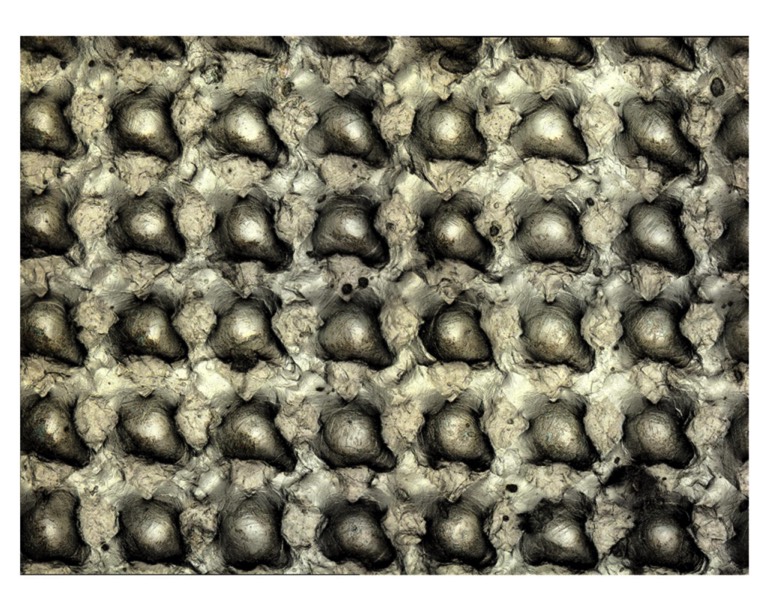

Micro Structuring

To increase the acceptance of implants it is state of the art to use a surface modification like glas bead blasting. The big advantage of an electron beam structured surface is the possibility to generate structures with defined dimensions. With the ability of a high frequency beam deflection hundreds of these microstructures can be generated in a few seconds. One possibility is SurfiSculpt® which is shown in the pictures below.

Surfi-Sculpt was invented by Bruce Dance at TWI in 2002, and has been the subject of on-going research and development. TWI has obtained granted patents for this technology in Europe, USA, Japan and a number of other countries (EP1387734, EP1551590, US6670571, US7667158 & others).

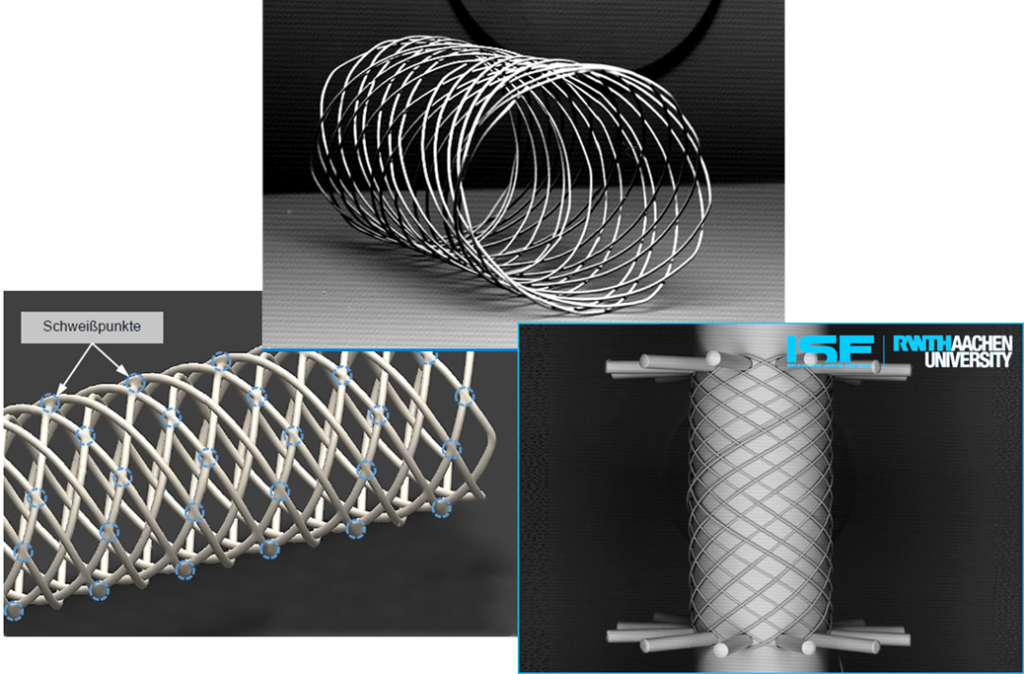

Micro welding of thin wires made of Nitinol

One of the interesting biocompatible materials for medical implants is the Nitinol, a shape memory and superelastic alloy, which consists of 50 at.-% nickel and 50 at.-% titanium. Micro Electron Beam welding allows to join Nitinol wires for example to increase the radial force of stents. The wire diameter ranges from 200µm down to 30µm.

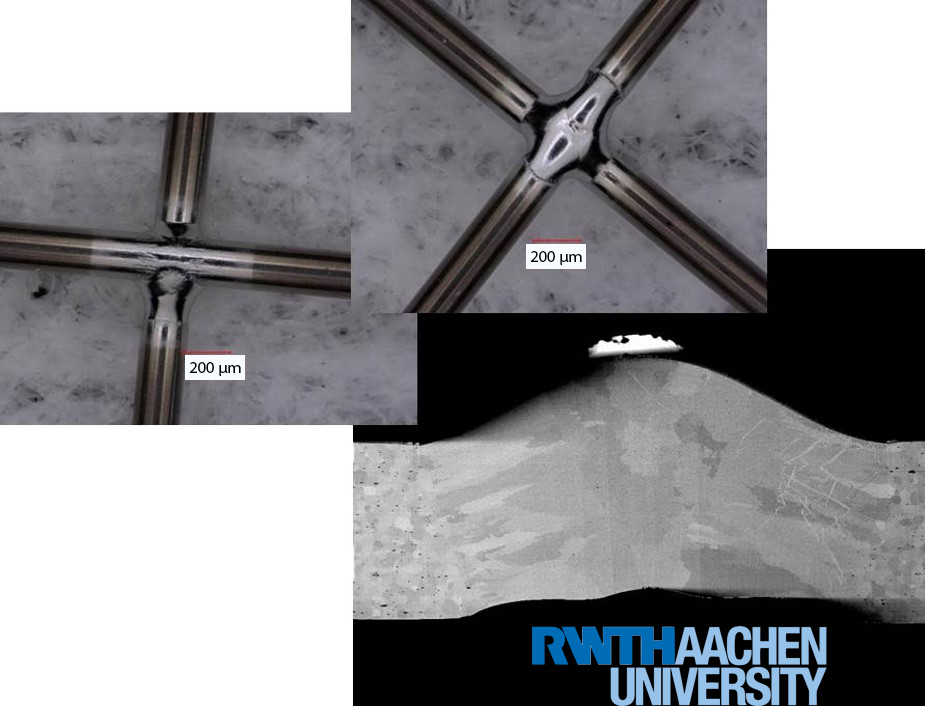

Welding of the wire crossings (left) of a one wire hand winded Nitinol stent.Electron optical pictures of a stent (upper) and (right) winded in a fixture prepared for welding.

Picture from welds (upper) of wire crossings

Cross section (lower) of spot welded stent of Nitinol wires

Beside the fine focused electron beam, power control in the sub watt regime is of essence:

Left: 140µA (8,3 Watt) beam current: molten wire

Top: 130µA (7,8 Watt) beam current: perfect joint

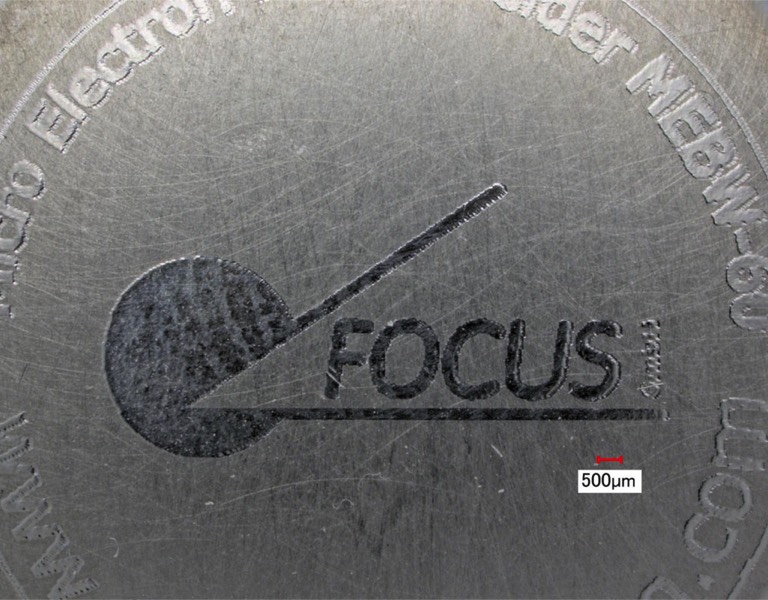

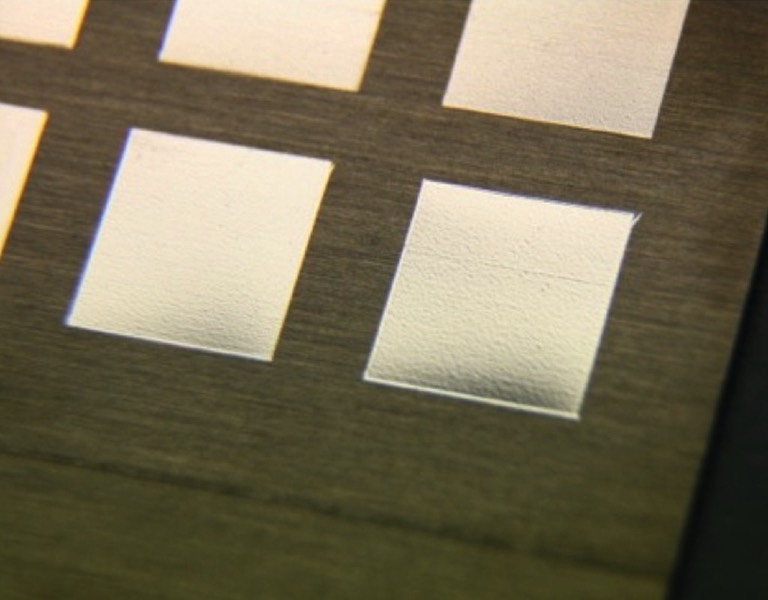

Engraving and polishing

Especially in the medical sector it is necessary to monitor medical components through their entire life cycle. With the implemented engraving technology it is possible to mark your parts directly after your welding process.

If a surface roughness of just a few microns or smoothening of edges is needed, the electron beam can be used for polishing. This technique is available for every metal surface and can be done in a few seconds.