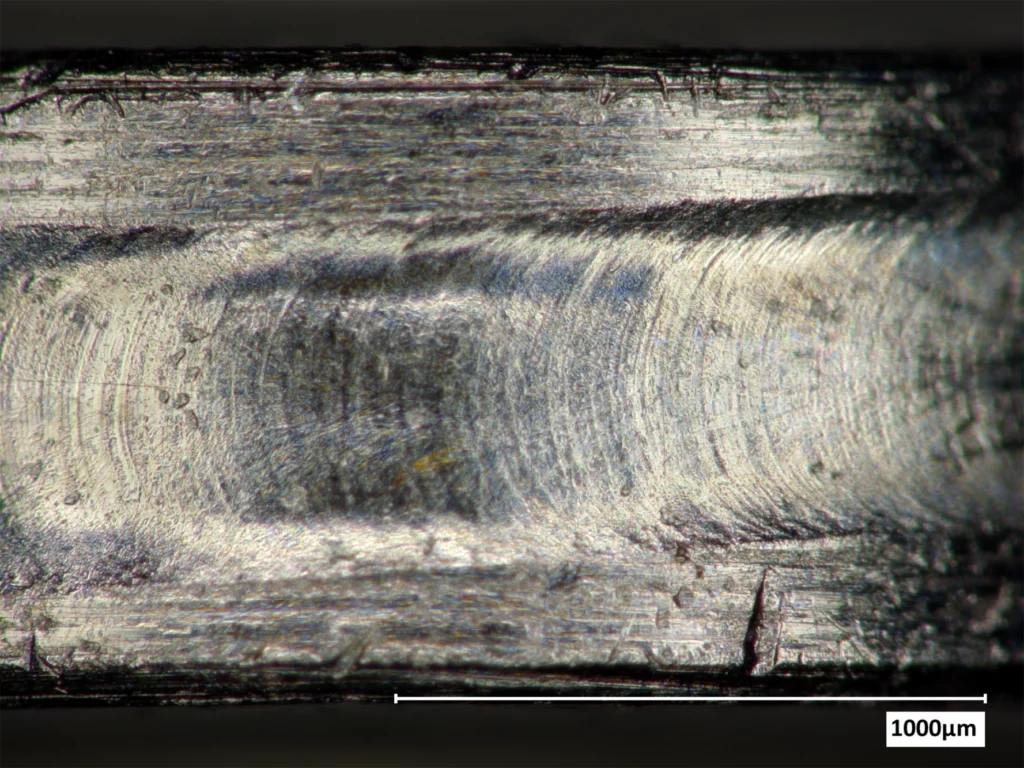

Welding a 50µm thin film on Invar© into a steel ring

Titanium and Zirconium

- Dissimilar welding

- Invar welding

- Thin film welding – 50 µm

Welding steel and Invar© (64% Fe + 36% Ni) can be challenging due to the different coefficients of thermal expansion and thermal conductivity. Invar is characterized by a very low coefficient of thermal expansion, while steel has a higher coefficient of thermal expansion. This creates significant stress at the joint as the weld cools, which can cause cracks and deformation.

The electron beam allows very precise control of the amount of heat applied to the heating area, minimizing the heat affected zone. Precise heat supply and excellent control of beam power are the features of FOCUS precision electron beam welders. The absence of cracks and deformations in thin films, in this case Invar©, depends largely on this. This also applies to welding steel with Kovar©, Havar© and other ferrous alloys.