Electron Beam Surface Modification

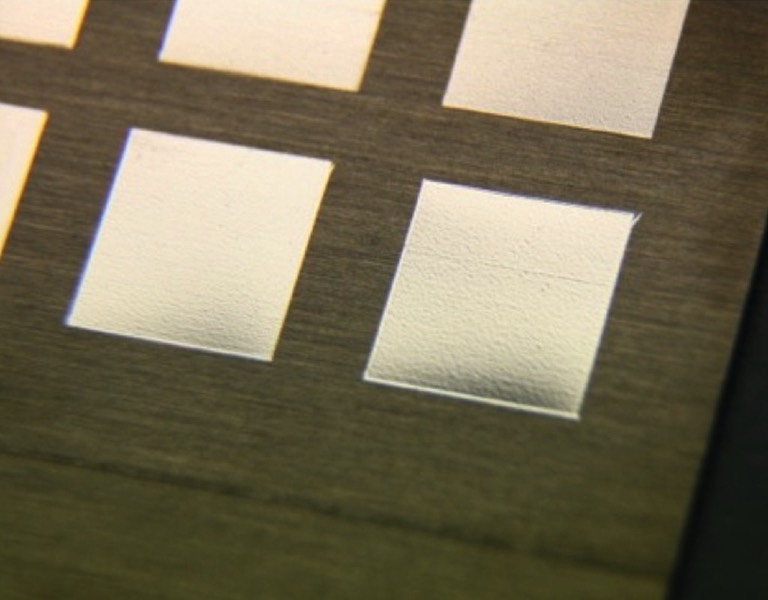

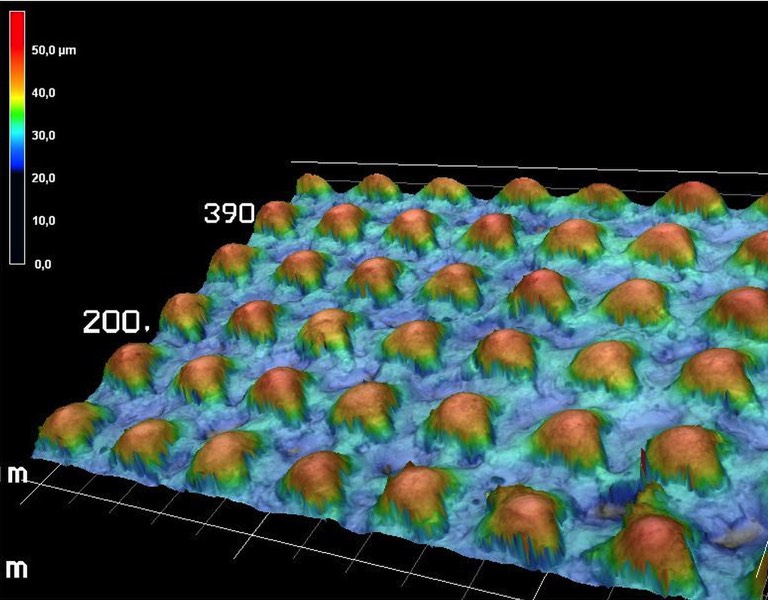

Surface Modification in the micro range by fast beam deflection can improve the joining properties of adhesive bonds and polymer-steel joints.

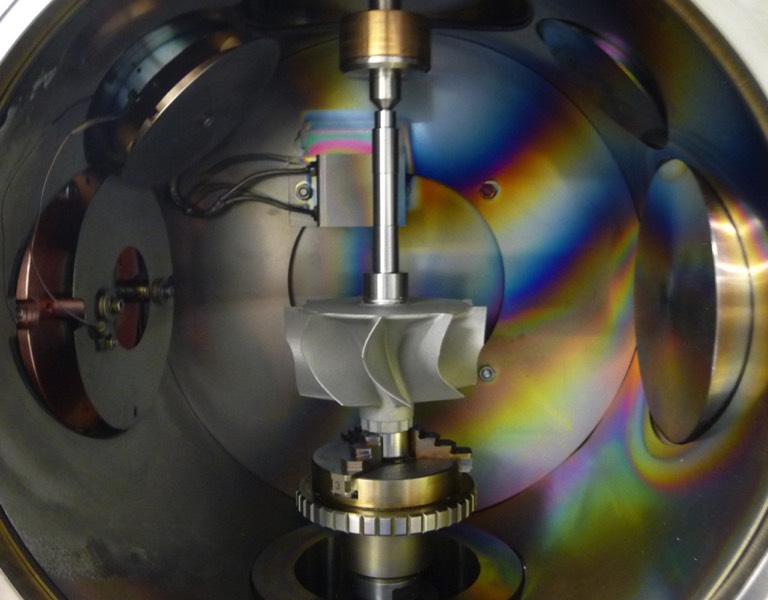

During electron beam hardening the surface hardness can be increased, depending of the carbon content, up to 1600 HV0.1. This can be done very accurately in a range of a few microns in width and depth. In the example below an axle of a turbo-charger is processed only at the bearing seats.

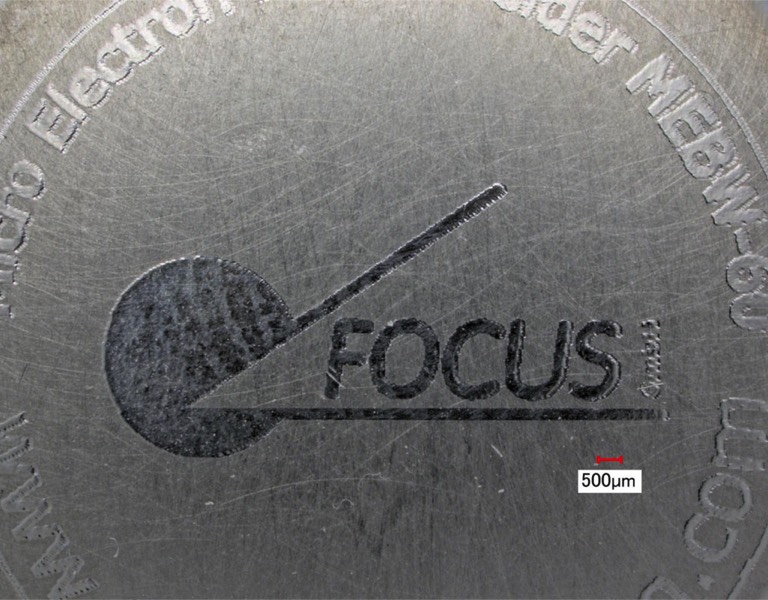

Every metal surface can be polished or engraved by an electron beam.

Surface Structuring

Surface Hardening

Engraving

Polishing